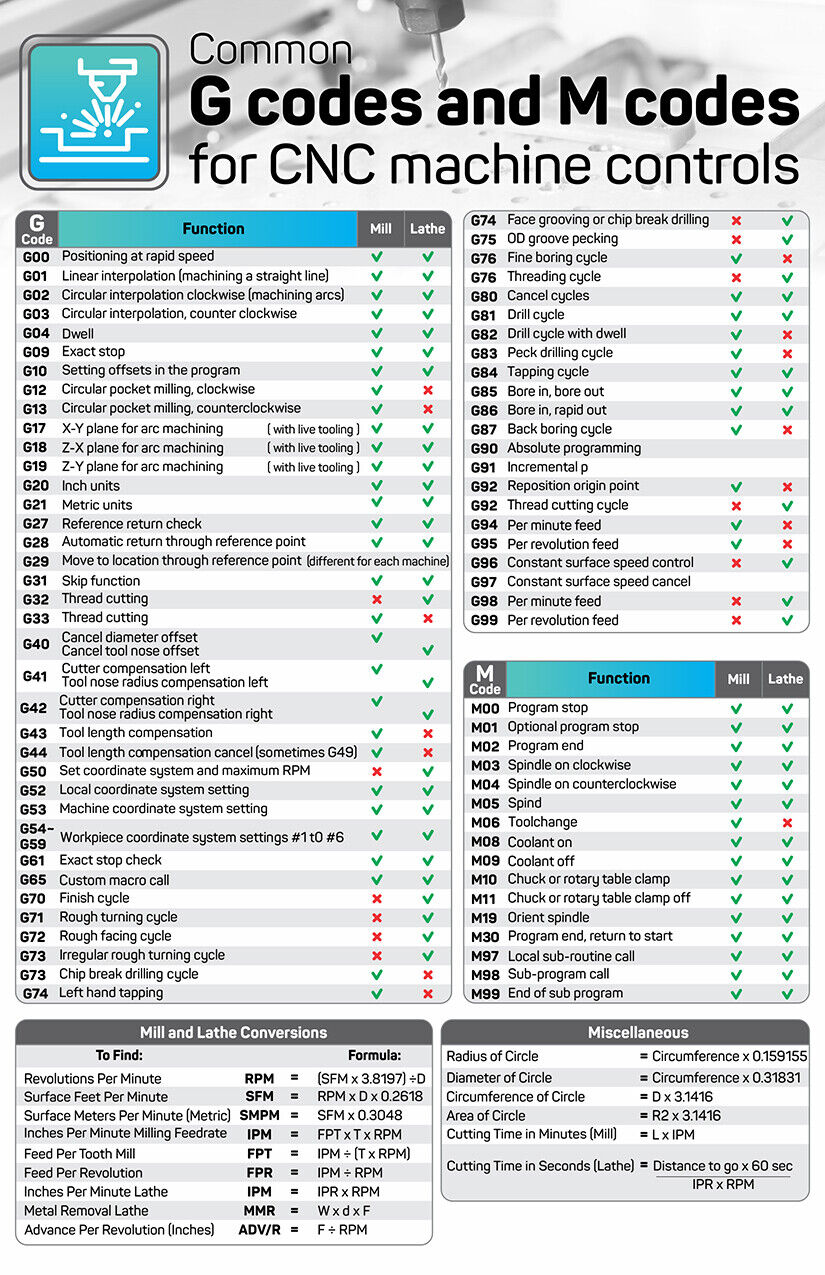

G-code activates the CNC machine, and M-code activates the machine's programmable logic controller. G-code commands often differ in CNC machines, while most M-code commands remain the same. CNC machines have transformed the manufacturing industry and simplified the process of producing precise and consistent parts.. From my experience, I can say that easily most of the codes are the same, but some manufacturers have special M-codes and G-codes. For example, some of the codes I found very helpful; G05.1 Q1: I used this code on Fanuc Milling controller-OM to activate highspeed machining mode with high precision mode. Machined parts are more precise with this.

G and m codes

CNC Milling G+M Code List Metalworking Industrial Equipment

Common GCodes & MCodes for CNC Machines Chart 5.5"x8.5" eBay

G and M Codes The Differences Explained CNC Masters

CNC G Codes Learn how to program CNC machines with GCode

G Code Alias M Code Alias (How to use them) CNC Training Centre

Understanding G and M Codes for CNC Machining RapidDirect

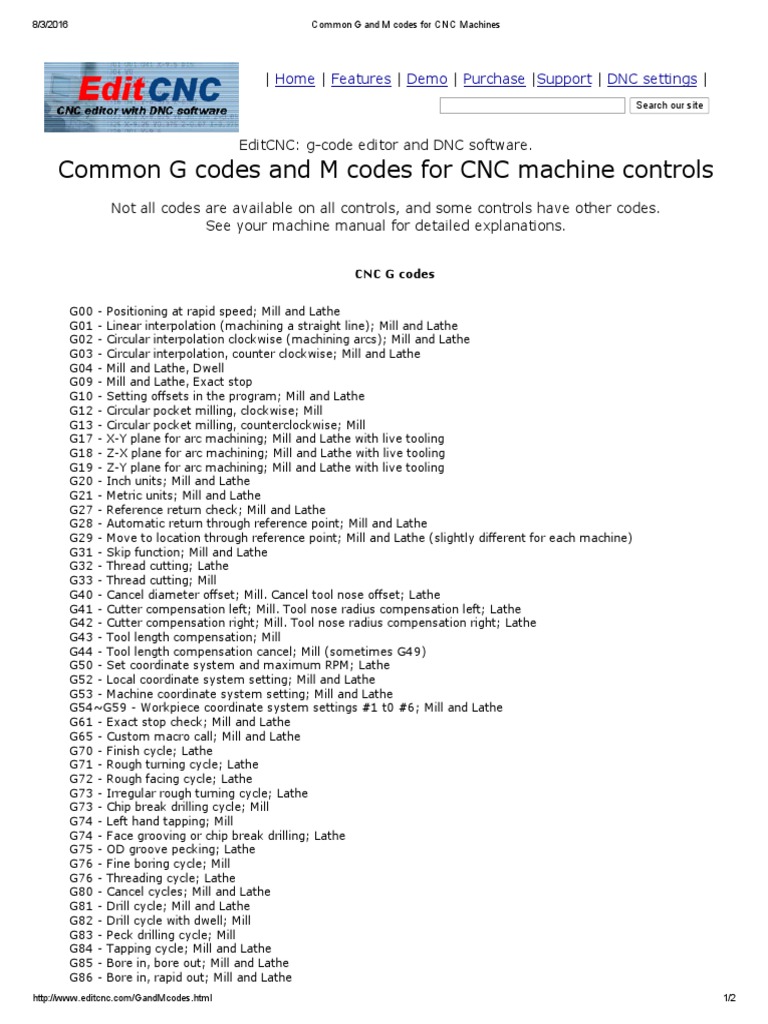

Editcnc Common G Codes And M Codes For Cnc Machine Controls Drilling Industrial Equipment

g & m Codes Cnc Programming Drilling Machining

Introduction About G Code and M Code In CNC Manufacturing SANS

Common G and M Codes for CNC Machines Drilling Industrial Equipment

G and MCodes In CNC Explained Difference, Usage And More.

Introduction About G Code and M Code In CNC Manufacturing SANS

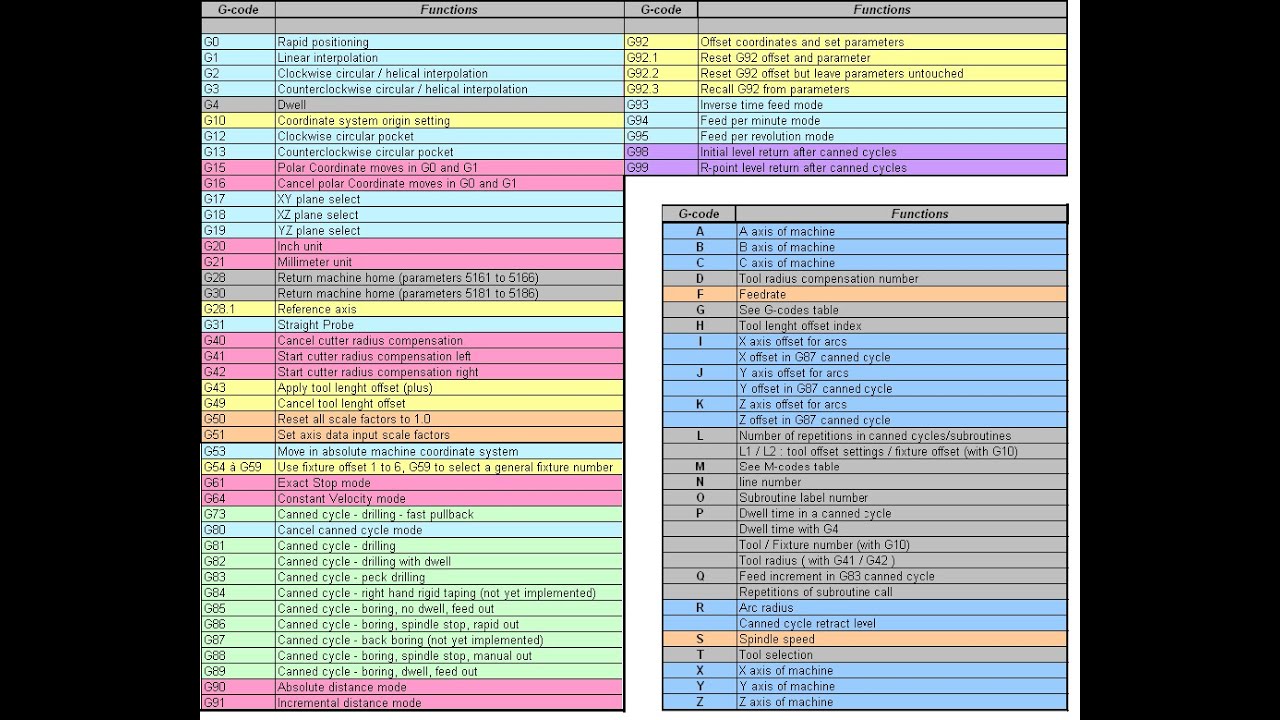

G Code M Code Reference Chart YouTube

Master List of CNC G and M Codes Drilling Machining

G&M Code Understanding CNC Programming Languages ETCN

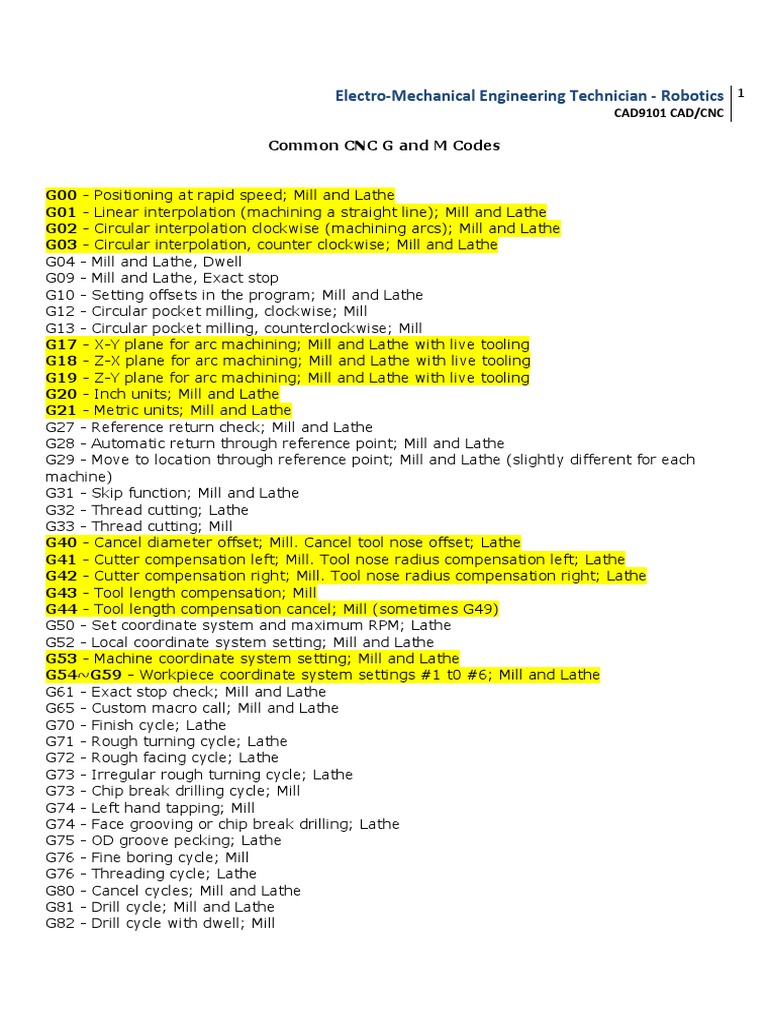

Common CNC G and M Codes Drilling Numerical Control

GCode and MCode Reference List CNC Milling SD Woodworking

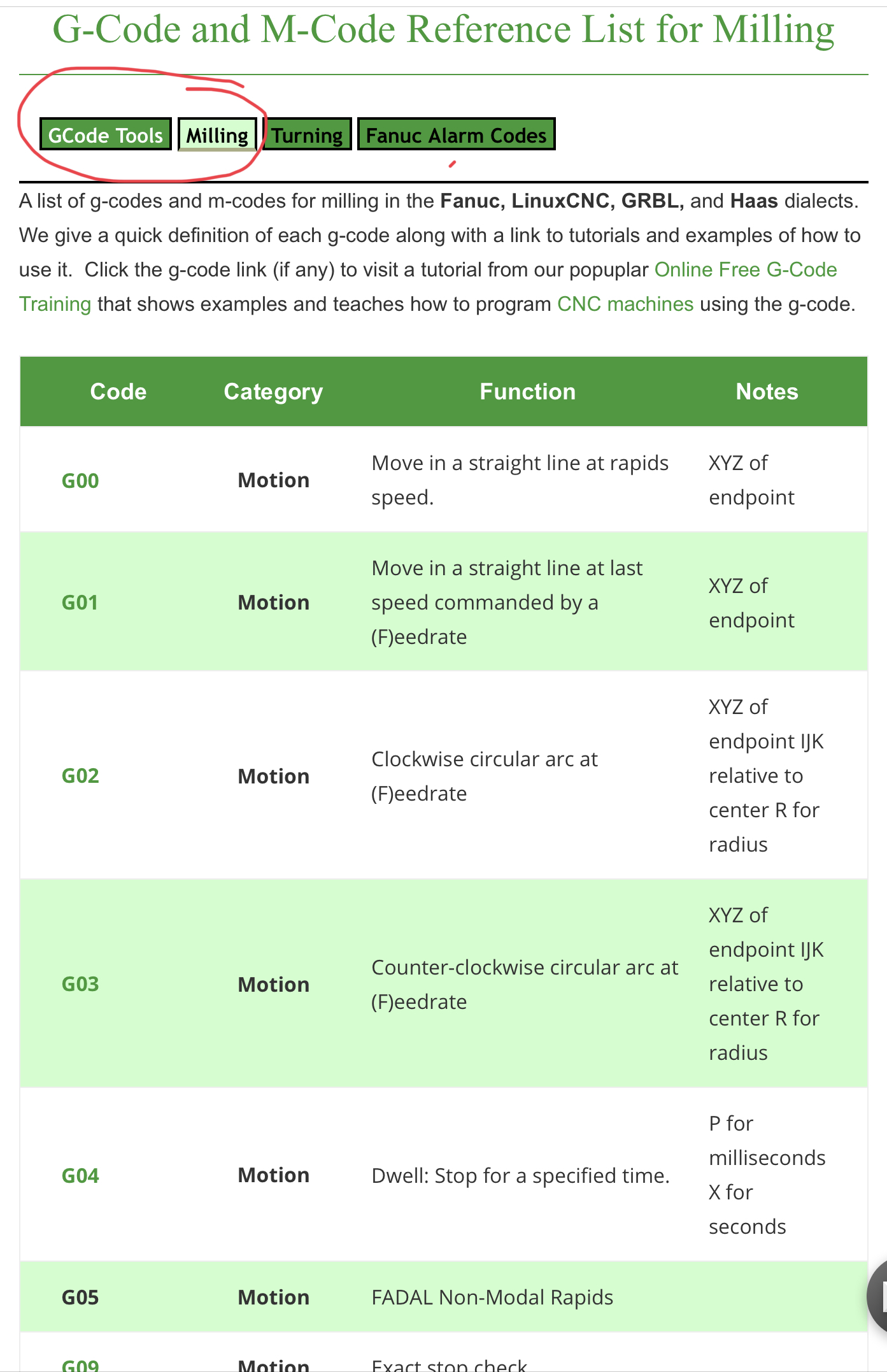

G & M Code Tables for Milling

![GCode and MCode List for CNC [ Easy To Use, Examples & Tutorials ] GCode and MCode List for CNC [ Easy To Use, Examples & Tutorials ]](https://www.cnccookbook.com/wp-content/uploads/2018/10/SimplifyGCode1200pxBtn.jpg)

GCode and MCode List for CNC [ Easy To Use, Examples & Tutorials ]

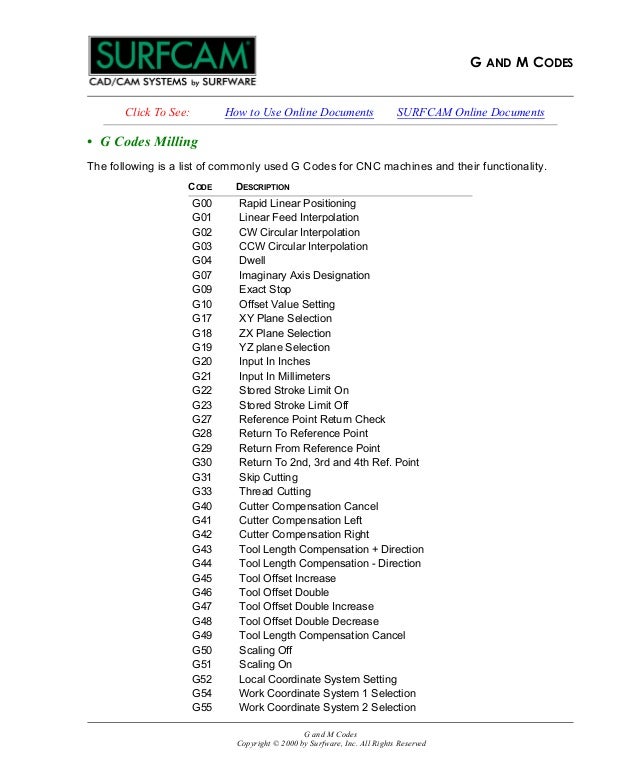

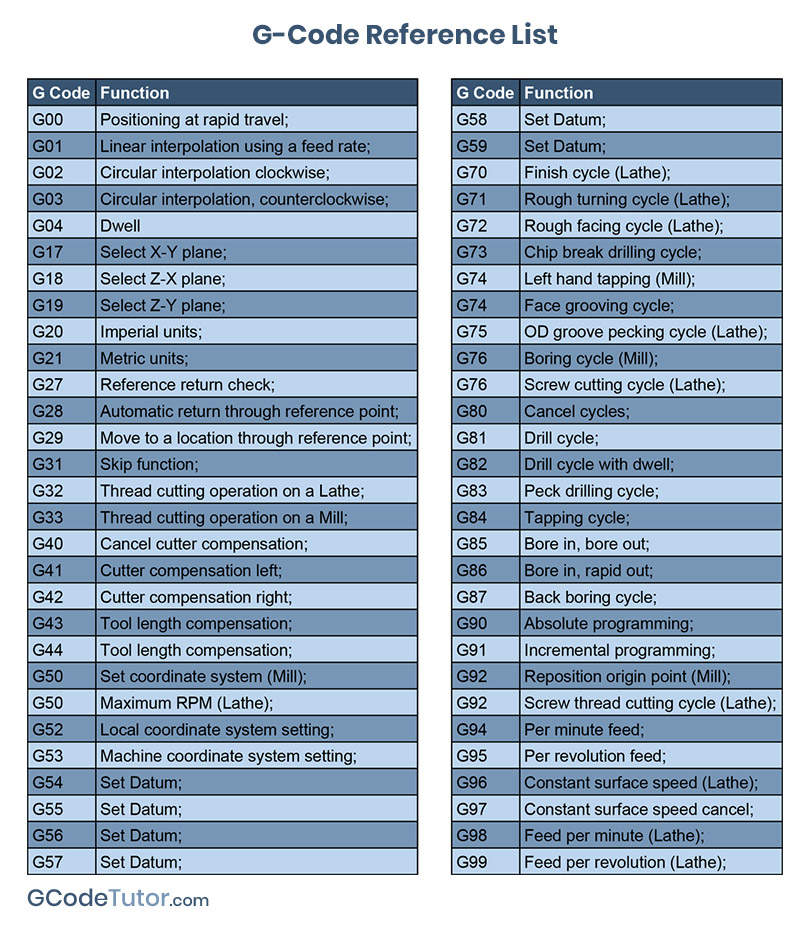

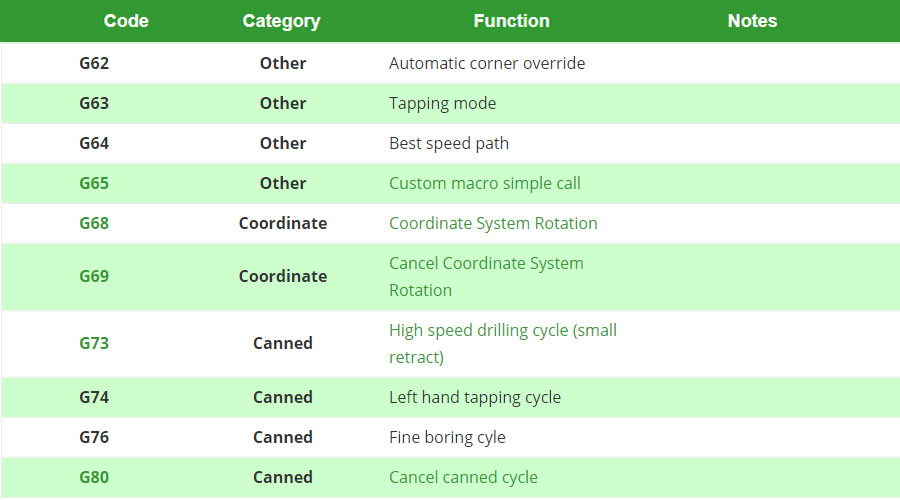

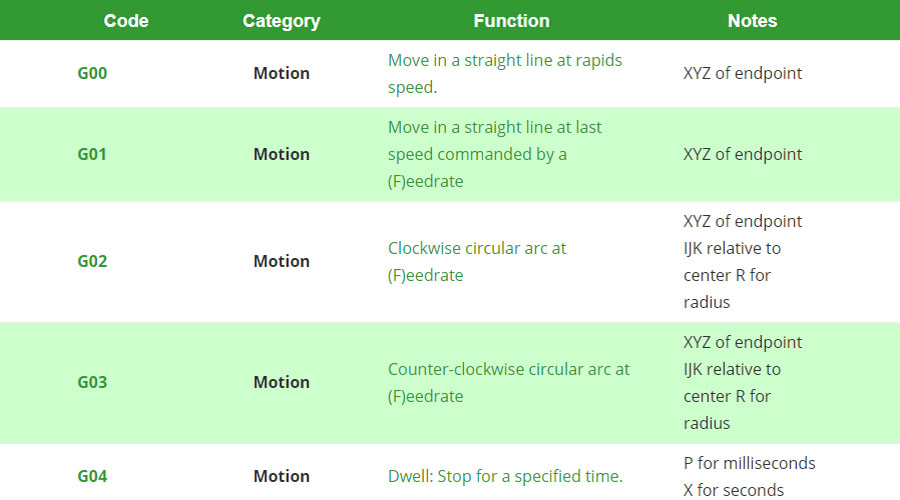

G codes for CNC milling. The following are some of the commonly used G codes and their description in CNC milling. G00 - Rapid positioning. G01 - Linear travel/interpolation. G02 - Circular travel/interpolation (clockwise) G03 - Circular interpolation (Anti-clockwise) G04 - Dwell. G10 - Programmable data input.. Summary of M-Codes All MachMotion CNC controls use the Mach3 or Mach4 software. Use the M-code list below as a reference. Download. Mach 3 G-Code Language Reference. Download. Mach 4 G- and M-Code Language Reference.